How can Thermal & EMC design work ‘together’?

This new course will be given ‘in pair’ by Norbert Engelberts of OTS and Mart Coenen of EMCMCC.

Both gained their theoretical and practical knowledge of engineering during their more than twenty five year work experience in the industry at many well-known OEMs.

Mostly thermal and EMC do not get along well together in your practice. During this one day course we are very pleased to explain several ‘tips & tricks’ and basic knowledge in order to let these two to work ‘together’ as optimally as possible.

You can make this course successful by being interactive and by bringing your questions and issues on the day itself and/or by asking these in advance. Please find here topics and subjects:

Level of components

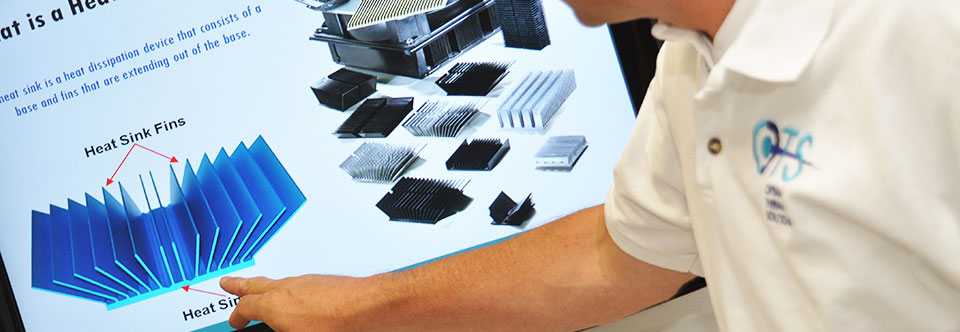

- What is the effect of attaching a heatsink to a component?

- Does this need to be electrically coupled or can it float?

- What are advantages and disadvantages?

- What to do with wireless (transmitter + receiver) environments, in which antennas need a specific radiation pattern in order to function optimally? What is the negative effect of a heatsink to this?

Level of PCB

- What is the effect of copper layers, earth- and power levels or impedance traces (a must for EMC, for thermal is copper the first ideal heat spreader)? How to let these work together as optimally as possible?

- What is the ideal board routing and distance?

- Where to place via’s and/or where to place consciously thermal/EMC separations in the several circuits?

- Grounding of heatsinks, cooling plates, chassis parts that will be potentially used for thermal?

- How to avoid HF-couples (noise)?

Subrack

- From thermal point of view it is desirable to make the subracks as open as possible in order to obtain ventilation. From EMC point of view you rather do not want to have crevices and a maximum hole size. What is the ideal EMC hole pattern in your housing that is also optimally thermal?

- What to do with possible capacitive couples?

- Application of air flow guides or dummy PCB’s in systems: should you perform these in aluminum or FR4 with/without copper? And should you/shouldn’t you connect with backplane/front plate?

Rack / enclosure

- In- and outlet grills and filters of the rack: from thermal and EMC point of view.

- Placement of the fans: in or outside the EMC boundary?

- What is ideal placement of the fan regarding the most optimal air flow?

- What is the ideal pattern of holes, both from thermal as well as EMC point of view?

- How to deal with cabling and other components and finishing? On one hand a thermal blockade but on the other hand a must for EMC filtering.

- Safety demands: how do they intervene in your EMC and thermal design?

This 1-day course is being held in cooperation with Telerex and is conducted in Breda and Antwerp.

Price: € 595,– excl. VAT – including coffee & lunch.

Date/ location: on demand.

Please take a look at the presentation of Slim Thermisch en EMC compliant ontwerpen – Coenen-Engelberts – EMC event Telerex.

Back to Training